Phone :

+039 0296788049

WELCOME !

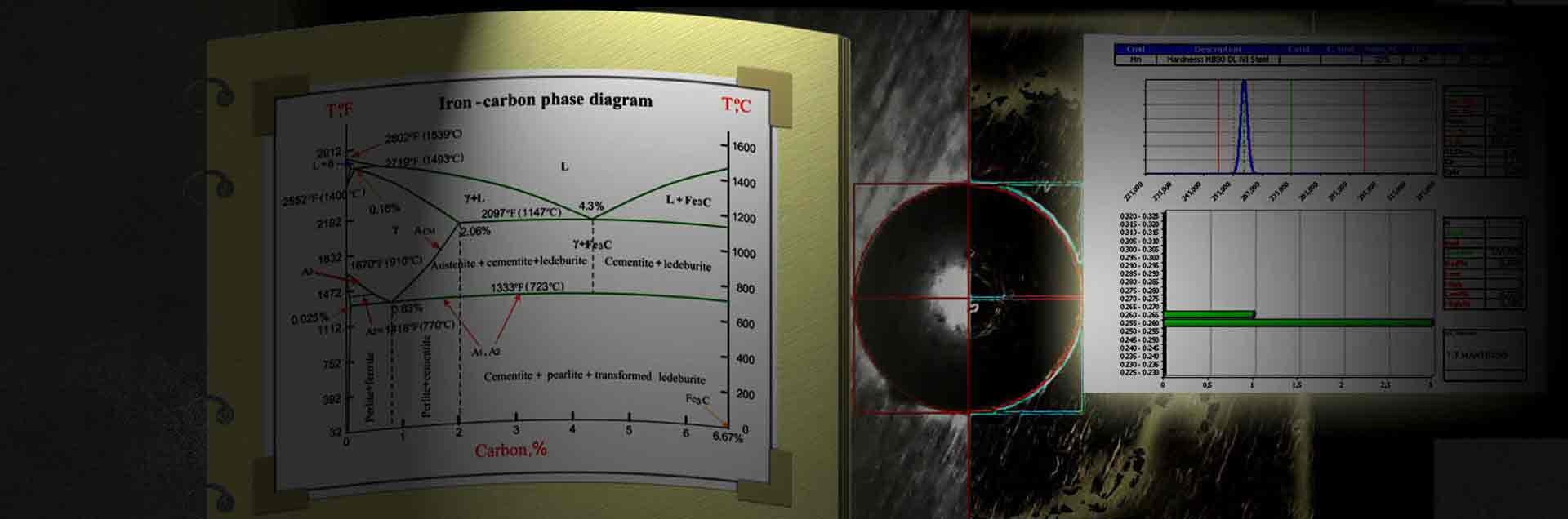

The carburizing is a metallurgical process used to increase the hardenss of teeth and resistance of steels ..

There are several methods of carburizing, according to the cementing substance, but it is stressed that the environment is always gaseous, as there is always the need of the addition of carbon on the surface of the material.

The history of our company goes back until the 50s, when it was founded by Italo Montepilli, naming it "Heat Treatment of Italo Montepilli".

From then until now, the year 2016, the continuous improvement of automatic control procedures and technologies for verification of hardness and with the use of larger furnaces, our company continues to improve and to increase its patronage park, in the continuation a serious policy and aimed at improving all aspects of production and customer relations.

New process consisting of a heat treatment carried on in a bath of salt, non-contaminating, by which, on mechanical parts in ferrous alloys, are obtained of fatigue strength increases, to wear and corrosion.

That's why this procedure was also named in the 1970s to the 1980s, and in the past quini "TE NI FER" a term no longer in use and no longer used, and created by the abbreviation of the Latin scientific terms "TENAX "(tough)," Nitrogenium "(nitrogen) and" FERRUM "(iron).

QUALITY CONTROL

Our qualified specialists

provide you with a full range of hardness tests for the quality of treatments.

DELIVERY

Our delivery times on the heat treatment are reduced while maintaining a high quality standard.

TREATMENT

A department of treatment, on which are inserted our furnaces that are divided for categories of treatments and for the capabilities of load..

YOUR ORDERS AND DELIVERIES

Treatments with the highest quality of each steel material (raw, welded, profile, steel, gears) with quick deliveries. .

ANNEALING

We will execute the processes of annealing isotermic for guarantee the lowest hardness and eliminate all problem in the post-working of pieces.

LABORATORY

A laboratory of quality control inserted in our firm where, according to the demands of the customers, certificates and diagrams are released for requested treatments.

PRELIMINARY CHECKS

We isolate specific types of steels for preliminary controls and their subdvision for each treatments needed.

SANDBLASTING

We esecute processes of sandblasting for polish and eliminate all impurity from the surface of all our pieces treated.

OUR SERIOUSNESS

The seriousness with which we treat our customers resulted in our success over competitors.

We live in a rapidly changing world, and we witness profound changes in society, consciousness, foundations, business.

But invariable were and still are the basic principles on which the activity of the company has been built - honesty in relations with customers and partners, an extensive range of products, consistently high quality of our cement, accessible prices, social responsibility, the desire for stability.

Hardness

Test

Ask for

Offers

We guarantee quality on all our heat treatments

What's new?

The satisfaction of our customers - that is the main task and mission of the company and in particular of the sales department. Our company is a competent and reliable partner. All our customers can always be sure in our assistance, support and obtain advice from our side.

Best treatment

Carburizing or carburization is the more used heat treatment process in which iron or steel absorbs carbon liberated when the metal is heated in the presence of a carbon bearing material, such as charcoal or carbon monoxide, with the intent of making the metal harder. The process of carburization works via the implantation of carbon atoms into the surface layers of a metal.

Inner control standards in all pieces treated

ARTICLES

DEVELOPMENT

Since the advent of the product we use natural resources. We understand that natural resources are exhaustive and should be used sparingly. We have defined development as a strategic goal.

OUR POLICY

But invariable were and still are the basic principles on which the activity of the company has been built - honesty in relations with customers and partners, an extensive range of heat treatments.

Known in the past with the name of the soft nitriding or Tenifer ™ treatment, it was born this new process consisting of a heat treatment carried on in a bath of non-polluting salt, by which, on mechanical parts in ferrous alloys, are obtained resistance increases to fatigue, wear and corrosion.

GALLERY